What is Fusion Engineering Platform (FEP)?

Korea boasts numerous precision manufacturers with capabilities across various fusion component areas, recognized for their expertise in manufacturing components for Korea's KSTAR fusion project and the international ITER fusion project. Korean manufacturers excel in areas such as superconducting magnets, cryostats, thermal shields, vacuum vessels, and power supply equipment.

While Korean manufacturers are renowned for their excellence in quality, scheduling, and cost-effectiveness, they have faced challenges in receiving orders directly from fusion developers due to the extremely demanding physical and engineering requirements.

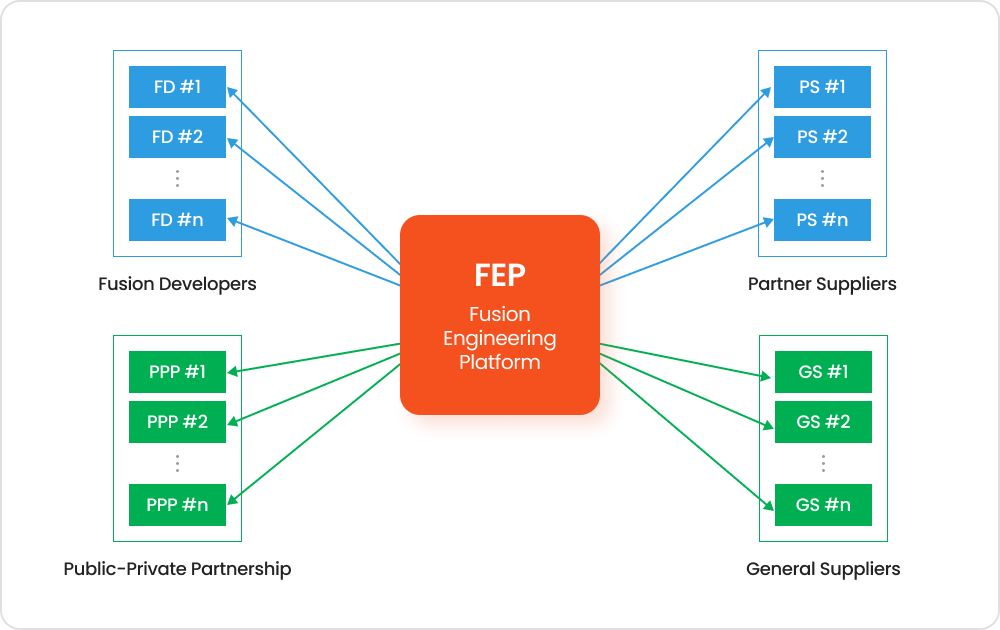

EnableFusion's Fusion Engineering Platform (FEP) bridges the gap between fusion developers and Korean precision manufacturers. This two-sided platform connects fusion developers and PPPs on the demand side with Korean manufacturers as partner suppliers on the supply side.

Comprehensive Services to Accelerate Development

EnableFusion transforms complex requirements from fusion developers into digitally re-designed and re-engineered specifications on the FEP. This digital design, along with manufacturing procedures and guidelines, is then provided to manufacturers to seamlessly produce fusion devices with guaranteed performance.

EnableFusion offers a full suite of services to streamline the development process.

EnableFusion's key roles with the FEP are:

- Requirements Translation: Interpreting complex fusion engineering requirements into actionable manufacturing specifications.

- Digital Re-design and Re-engineering: Optimizing component designs in digital twins for manufacturability and performance.

- Outsourcing & Project Management: Coordinating with suppliers and managing complex projects.

- Engineering Guidance: Providing expert advice throughout the manufacturing process.

- Quality Control & Assurance: Ensuring all components meet the highest standards of quality and performance.

- Delivery & Installation: Managing the logistics of component delivery and installation.

- After-sales Services: Providing ongoing support to ensure optimal performance of delivered components.

With this full suite of services, fusion developers can evaluate and develop new desired technologies much faster. EnableFusion's success will significantly accelerate commercialization by allowing fusion developers to focus solely on new fusion technologies without manufacturing concerns.

EnableFusion will conduct all re-design and re-engineering digitally on the FEP using digital twins and AI, providing cyber-physical simulation capabilities to further accelerate commercialization for fusion developers.

EnableFusion envisions playing the foundry role in fusion similar to NVIDIA's in AI, with an initial goal to "help fusion developers accelerate commercialization by enabling them to order, install and evaluate desired fusion devices as easily and quickly as possible."

EnableFusion’s Core Competencies to Strengthen FEPs

Expertise in interpreting requirements from Fusion Developers

- Comprehensive understanding of cutting-edge Fusion technology, engineering, and industry trends

- Experienced engineering team with internationally proven experience and reputation

Requirements Translation, Digital Re-engineering, and Engineering Guidance

- Converting fusion developer’s requirements so that Korean precision manufacturers can understand and respond to them

- Performing digital re-engineering to provide engineering guidance for easy and accurate production

Efficient Outsourcing and Project Management

- Meeting desired quality, price, and delivery requirements

Quality Control & Assurance

- Providing fusion developers with confidence in quality and delivery to support commercialization

- Supervising Korean manufacturers to ensure quality and delivery to meet fusion developers’ standard

Three FEP Categories to Drive Acceleration

-

01FEP for

Fusion Components

and Systems -

02FEP for

Fusion HTS -

03FEP for

Fusion AI

EnableFusion supports three categories of FEPs in the field of fusion components and systems, fusion HTS, and fusion AI. All three FEPs operate on similar principles. The details of how FEP bridges the gap between fusion developers and fusion suppliers are explained above, using the “FEP for Fusion Components and Systems” as an example.

FEP for Fusion Components and Systems

- Taking fusion component orders from fusion developers and PPPs

- Digitally re-designing and re-engineering for smooth production by Korean manufacturers

- Providing engineering guidance for guaranteed production

FEP for Fusion HTS (High-Temperature Superconductors)

- Assembling REBCO-based HTS wire, cable, and magnet companies to lead fusion HTS development

- Connecting fusion developers with fusion HTS companies in Korea

- Testing fusion HTS wire, cable, and magnet in conjunction with the KENTECH’s “HTS Conductor and Magnet Test Facility”

- Superconductivity testing under thermal cycle and electromagnetic load environments

- Magnet testing of charging/discharging performance and mechanical/hydraulic/electric insulation under room temperature and cryogenic qualification

FEP for Fusion AI

- Developing AI solutions for fusion with Korea’s specialized AI companies

- Providing an AI Platform covering all areas for fusion AI

- Material discovery

- Component design and development

- Manufacturing support in conjunction with digital twin

- Reactor simulation, control, and operation

- Supporting an AI surrogate model-based cyber-physical simulation at customer sites

- Supporting both ML models and fusion-tuned LLM models

- Leading the "AI4Fusion Deep Dive Colloquium" for collaboration within the Korean fusion AI community